Mud School 101: Essential Training for Drillers

Is mud school necessary for the average driller?

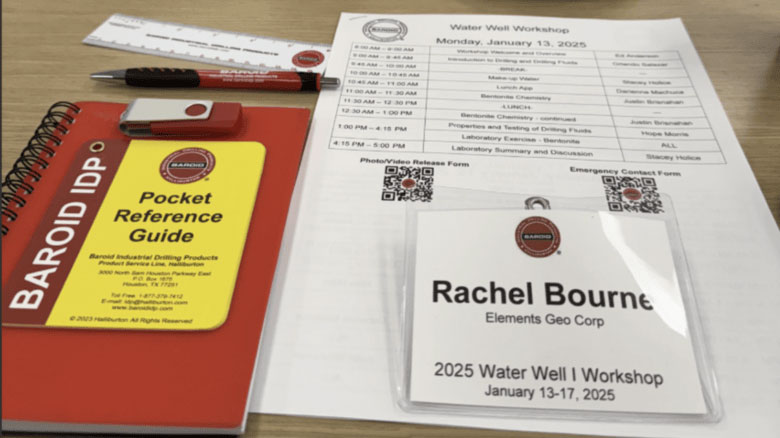

Image courtesy of Rachel Bourne

What exactly is “mud school?” Mud school, or formal training programs in drilling fluid engineering, have been around since at least the mid-20th century. Major drilling fluid companies like Baroid, MI SWACO, and Baker Hughes started offering structured training programs for mud engineers as early as the 1950s and 1960s. These programs evolved alongside advancements in drilling technology and the oil and gas industry.

Technically the proper term is a drilling fluids course for water well applications, but mud school just sounds more fun. At mud school, participants learn how to optimize drilling fluids to enhance the efficiency of drilling operations.

Or more specifically…

Topics Covered in Mud School:

- Drilling Fluid Properties: Identifying and testing drilling fluid characteristics.

- Clay Chemistry: Understanding how clay composition affects drilling fluids.

- Fluid Dynamics: Exploring the impact of fluid movement on drilling performance.

- Polymer Usage: Enhancing drilling fluids with polymers for improved performance.

- Hole Cleaning: Techniques for effectively cleaning drilled holes.

- Mud Contamination: Identifying and treating contaminants in drilling fluids.

- Grouting and Hole Abandonment: Proper methods for sealing and abandoning drilled holes.

So, how did I get here? Well, connections! More specifically, I called my Baroid rep to learn about new materials, ask for their assistance on projects, and utilize their training. He put my name forward and I was accepted to take the course!

The benefits: A broad overview of my daily work, along with insights into how I—and many others—might not be using our products to their full potential. The class goes over why measurements are important, how to get the best bang for your buck, proper mixing techniques, and the chemistry make and background. We collaborate in a group, sharing our experiences and discussing the tools and techniques we use, allowing us to learn from one another.

Image courtesy of Rachel Bourne

The hands-on portion was awesome. Practicing all the ways to test your mud in a lab to see how they react, why they react or if there is something you can do to stop items from reacting with your fluids to get you the best hole you’ve ever drilled every single time.

More people need to experience this training. It’s not just for drillers! Geologists, engineers, suppliers etc should experience this. Realizing that there’s still so much more to teach when it comes to drilling, it’s clear we need more hands-on and in-class training.

A huge catch phrase you hear here in the drilling companies is “this is the way we’ve always done it” and that’s how you learn about this stuff but the main item I took back from mud school is the way I was taught to do it maybe isn’t right or the way it should be done.

What do I think needs to happen in the future? More people need to experience this training. It’s not just for drillers! Geologists, engineers, suppliers etc should experience this. Realizing that there’s still so much more to teach when it comes to drilling, it’s clear we need more hands-on and in-class training—at least for reviews and continuing education. This course covered an overwhelming amount of information, making it difficult to retain everything.

However, I don’t need to memorize it all—I just need to apply the tools and pass them on to my crews. The reps were incredibly helpful, offering their direct contacts, and I know I can always reach out to the local rep who nominated me for support.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!