What Drillers Need to Know About Viscosity

Get Acquainted with the Terms, How to Test Drilling Fluids

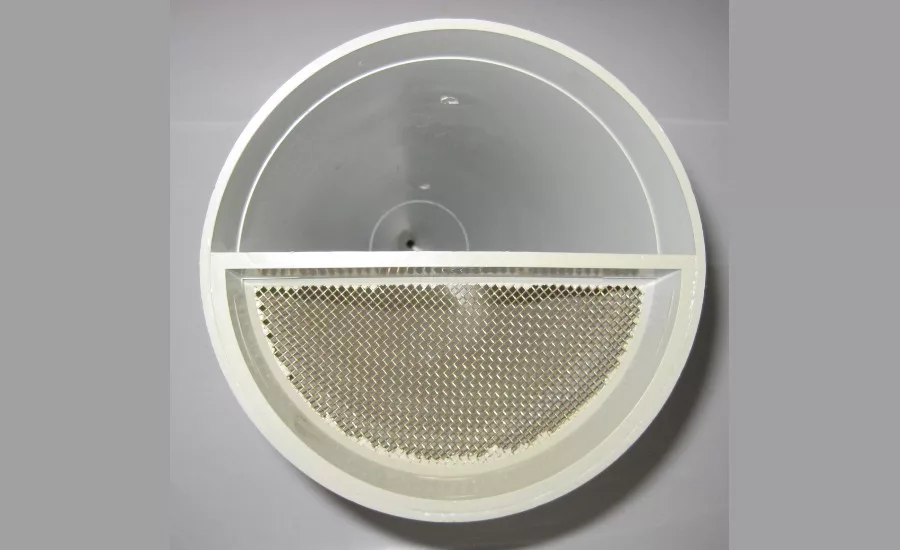

A Marsh funnel tells you the viscosity of the drilling fluid you’re dealing with in seconds. Remember that water at sea level has a viscosity of 26 seconds.

Source: Chemical Engineer / CC BY-SA (https://creativecommons.org/licenses/by-sa/4.0)

I would like to start with a hope that you and your families are staying safe. This month and next month, we will discuss the many descriptions and definitions of viscosity as it applies to drilling fluids. Key topics include:

- When to use a high-viscosity fluid and when to use a lower-viscosity fluid.

- How soil conditions dictate the viscosity and, ultimately, the successful results of the bore.

- What viscosity is and why it can act as friend or foe.

- Debunking some of the terms you hear when talking about viscosity.

Viscosity, the word, is derived from the Latin viscum, a word for both mistletoe and a viscous glue made from mistletoe berries. To confuse the issue even more, we often hear these terms to describe a drilling fluid: plastic viscosity (PV), apparent viscosity (AV), yield point (YP), shear thinning, Newtonian, and non-Newtonian. How do we put this all together so it makes sense?

Plastic viscosity is the resistance to the flow of a fluid in bores. This resistance is caused by the mechanical friction within the drilling fluids between solids and liquids, and the deformation of liquid under shear stress/pressure.

Apparent viscosity is the shear stress applied to a fluid divided by the shear rate. For a Newtonian fluid, it is constant. But for Non-Newtonian fluids, it is directly affected by the shear rate.

Newtonian fluids, which include pure water, have a predictable viscosity and will always flow predictably, regardless of the forces acting upon them. They also have predictable viscosity changes that are pressure and temperature sensitive.

Non-Newtonian fluids, such as drilling fluids or slurries, do not follow Newton’s law of viscosity. For these fluids, viscosity can change when under force to either more liquid or solid, hence the term “shear-thinning” fluids.

First, how do we test for viscosity? Dipping your hand in the tank and counting the drops that fall off your fingers is not an option.

Fluids are shear-thinning if the viscosity decreases as the shear rate or pump pressure/flow increases. With polymer slurries, the alignment of polymer chains results in decreased viscosities. In colloids (that is, bentonite) segregation of the particles/platelets in the flow causes a shear-thinning behavior. At rest, both polymer and bentonite slurries display a viscous, gel-like structure, but flow almost like water when under stress/pressure.

Are you mesmerized yet? All these terms can be overwhelming, to say the least. But, as a driller in the field, you need to break it down to a useable definition.

First, how do we test for viscosity? Dipping your hand in the tank and counting the drops that fall off your fingers is not an option. The easiest and fastest way to determine a fluid’s viscosity is with a Marsh cup and funnel:

- While putting a finger on the outlet of the funnel, fill the funnel by pouring it over the screen. Make sure to fill to the line just below the screen.

- Remove your finger while starting the stopwatch, and let the fluid flow into the cup to the line closest to the top of the cup.

- Stop the watch.

Your viscosity is in seconds: If it says 35 seconds, you have a 35s viscosity, and if you show 1 minute and 20 seconds, you have 80s viscosity. Remember that water has a 26s viscosity.

How do you decide which viscosity to use based on ground conditions? For coarse or un-consolidated soils, the range is 50s to 90s. For clays, the range is 35s-40s. For unknown conditions, shoot for the middle at 50s-60s.

If we do not pretreat our water with soda ash, we’ll never get the full yield or viscosity we should expect based on pounds/100 gallons of bentonite. Bentonite slurries perform best with a pH of 8.5 to 9.5.

We’ve gotten into a lot of viscosity-related vocabulary this month that drillers might need to know, as well as basics for testing viscosity in drilling fluids. Next month, we’ll get into the details of how viscosity affects mud pump performance. Until then, stay safe. We will get through these difficult times together.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!