How Do you Prove Geothermal HVAC Effectiveness?

ASHRAE headquarters is an HVAC laboratory. Source: Jay Egg images

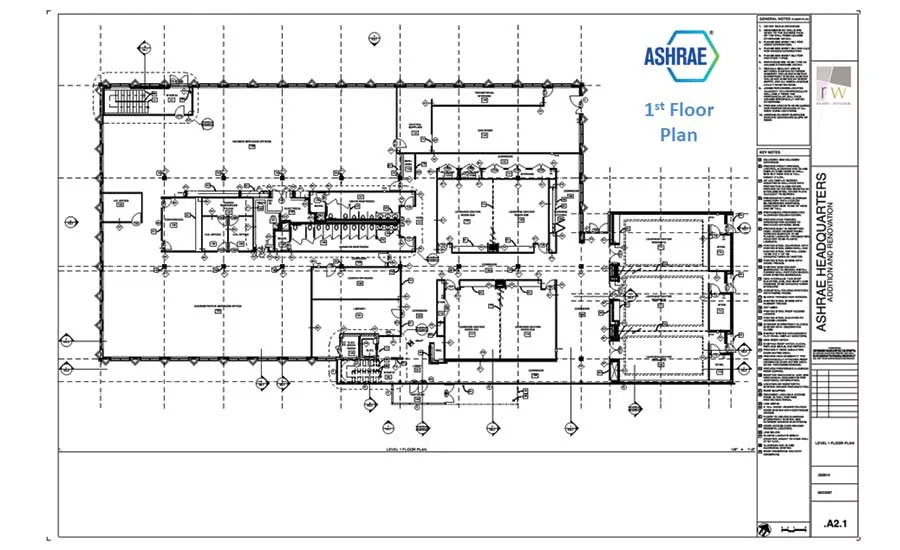

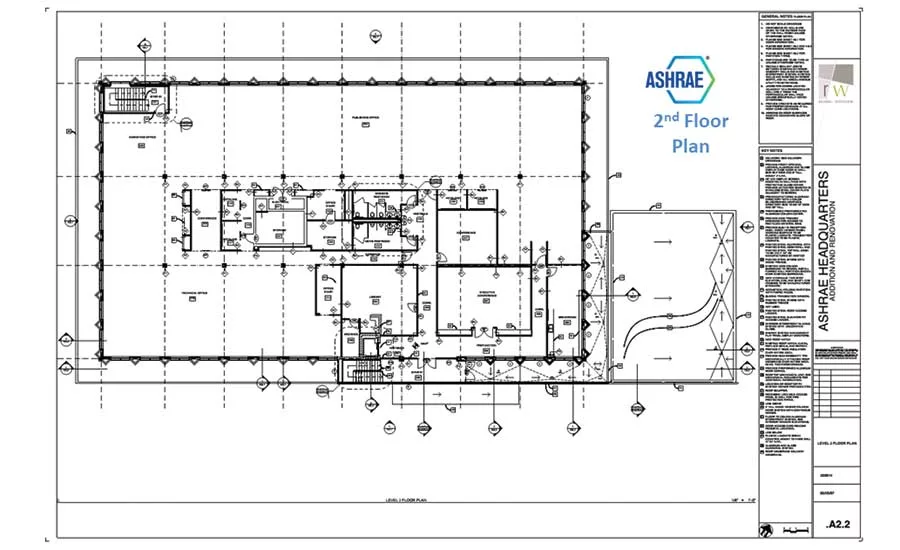

ASHRAE’s headquarters has variable refriderant flow on the first floor, and a geothermal system for the second floor.

ASHRAE’s headquarters has variable refriderant flow on the first floor, and a geothermal system for the second floor.

Geothermal heating and cooling systems are time proven, rock solid works of art that provide great benefits from every conceivable angle in a building’s HVAC system. Many ask, what might be done to reduce first cost? That’s not a question most mechanical professionals wish to tackle, primarily because of the involved nature of the geothermal exchanger.

While the building equipment and distribution side of the equation is reasonably predictable, the geothermal exchanger design can vary according to climate, geology and drilling subcontractors. A ground loop exchanger in New York City may cost twice that of an exchanger in Illinois. Much of the cost goes into drilling, properly inserting the pipe and grouting the boreholes, which may be $8 to $20 per foot or more depending on geology and location. And, just like the sizing of an HVAC system, no mechanical professional wants to be on the losing side of an undersized geothermal exchanger.

In the engineering world, there are allowances, or safety margins for error. Similarly, good geothermal exchanger designs would err on the side of caution, allowing for greater length, rather than too little pipe. But at $20 per foot for drilling costs, the costs for safety margins can quickly add up to five or six figures.

One retired individual thinks that he has a tiger by the tail, and folks are starting to listen. Dennis Koop, a retired engineer and executive started applying economics to geothermal designs just like he did to refineries in the oil and gas industry, and noticed a common theme that he took to the proverbial drawing board. He wrote a program he calls GeoHourly that models geothermal exchanger design and simultaneously does the energy analysis in a way that he believes is more precise, and can save the industry millions of dollars in installation, or “first-costs.”

In commercial design, the HVAC industry often uses the hourly method for calculating heating and cooling loads, but integrating the economics and design simultaneously was a challenge for geothermal systems. Water makes the geothermal system more efficient and the performance is driven by the water temperature from the earth rather than outside air temperature. Let’s consider the ASHRAE headquarters in Atlanta. The building is a living laboratory with two different types of HVAC systems installed.

The building is two stories with similar conditioned areas on the first and second floors, and was designed with a geothermal heat pump (GHP) HVAC system on the second floor (15,558 square feet), and a variable refrigerant flow (VRF) system on the first floor (18,226 square feet). The building has a dedicated outdoor air system (DOAS) for supplying fresh air to both floors.

For a little history, in 2008, ASHRAE’s headquarters went through a major remodel with the object in mind to evaluate sustainable building energy performance. Included were improvements such as lighting, solar PV and insulation. In order to facilitate reporting of performance, an array of more than 1,600 sensors to monitor HVAC performance was installed in the building. Data loggers have been used to provide historical data, and they continue to provide data today. With all of that data available, it was only a matter of time before some studies came to light.

In 2013, a research team from Oak Ridge National Laboratory (ORNL) and Oklahoma State University (OSU) were contracted to evaluate the performance of the HVAC systems at the ASHRAE building. Xiaobing Liu, Ph.D., and J.D. Spitler, Ph.D., teamed up to crunch the data. These researchers have been studying the relative performance of VRF and GHP that control the temperatures in the ASHRAE building. Those reports are available in the AHSRAE Journal publications as technical features, starting in the September 2014 edition. The report has been published in its entirety by the Geothermal Exchange Organization (GEO), and is entitled, “Performance of the HVAC Systems at the ASHRAE Headquarters Building.” To summarize, the paper reported that for the two-year time span of this study (2012-2014), the VRF system used 98 percent more total energy than the GHP system, 41 percent more in the summer cooling season (May–September) and 172 percent more in the winter and shoulder seasons (October–April).

This particular project was excellent for a review of the GeoHourly software. ASHRAE and the International Ground Source Heat Pump Association (IGSHPA) have at times suggested that excess pipe installed in the ground would make the geothermal system more efficient and economical. Doing the simultaneous design and energy cost evaluation has shown that, even if the efficiency is increased a small amount, the extra pipe installed in the ground loop to achieve the extra efficiency is not a good investment and may have a payback of 100 years, or return on investment (ROI) of many decades.

According to Dennis Koop, this payback is not obvious, and existing geothermal heat pump design methods don’t do the energy cost analysis and compare the ground loop installed cost in a way that allows designers to see that the excess design contingency is a waste of money. As mentioned earlier, the ASHRAE headquarters has geothermal systems installed with results from monitoring actual geothermal heat pump operations and ground loop temperatures. Using this real-world data, geohourly.com was able to simulate the ground loop length to within 2 percent of the actual installed length, and the operating cost to within 1 percent of actual energy cost.

The accuracy of GeoHourly is achieved because it simulates the building’s schedule that operates the heat pump equipment hourly in each individual zone. In order to perform this task, 9,100 calculations are completed in one second, including changing the first- and second-stage heat pump hourly performance to load conditions in each individual building zone.

With water-sourced HVAC equipment, we intuitively know that cooler incoming condenser water will increase the performance of the system. More pipes in the ground will help ensure lower incoming temperatures. Where is the sweet spot? I was surprised, and I think you will be, too.

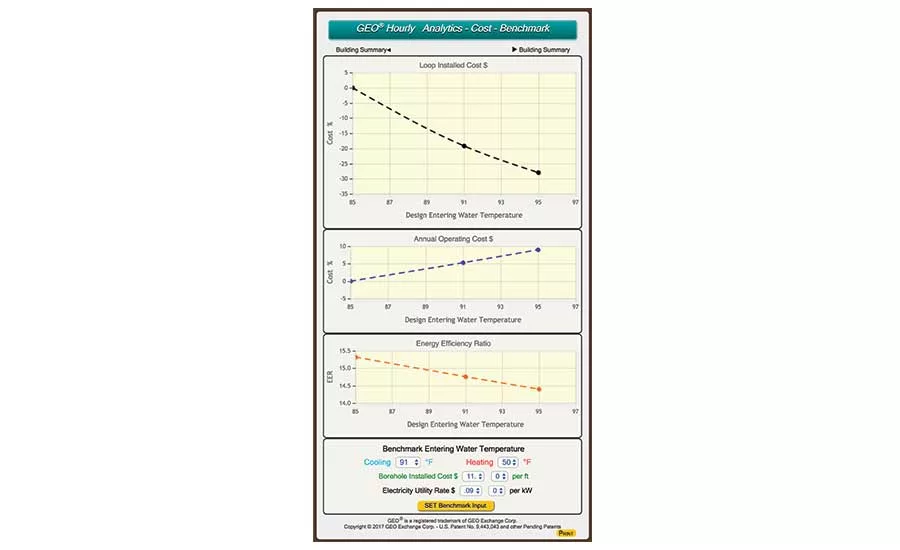

As you can see in the Analytics – Cost – Benchmark graphic, an increase of incoming condenser water from 85 degrees Fahrenheit to 95 degrees Fahrenheit:

- Decreases the loop-field cost by 28 percent.

- Increases annual operating cost by 9 percent.

- Decreases the EER from 15.3 to 14.4.

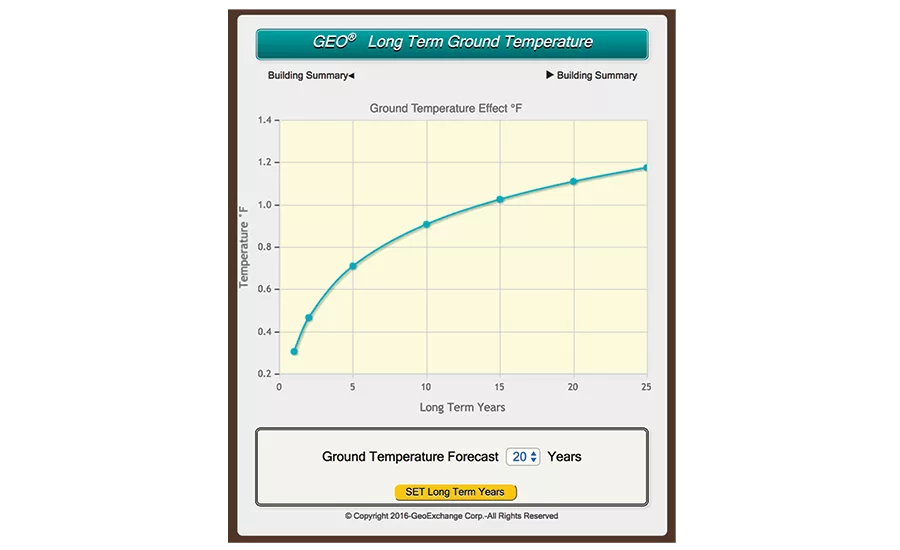

This is information that we can use to make educated decisions. Another consideration is a phenomenon we call temperature glide or contingency. This is the condition in which the earth temperature goes up each year due to cooling dominant buildings rejecting more heat than they extract. Knowing this effect is important, and adding a margin of design contingency protects the public welfare.

In this case, a quick look at the 25-year mark indicates that the temperature is starting to level out at about 1.2 degrees Fahrenheit above the undisturbed earth temperature at 25 years.

Government and third-party investors are interested in ways to control first cost of geothermal installations and establish a benchmark on quality. Tools that can provide reasonably easy data input and provide comprehensive results are needed to help more professionals gain access to important design information.

By all indications, using the hourly design method can offer the greatest benefits because it yields accurate, sophisticated system comparisons. As I said before, I think that Dennis Koop and his GeoHourly software may have the “geothermal tiger” by the tail.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!