Tech Topics: Non-Pressurized Tanks Help Well Supply Meet Demand

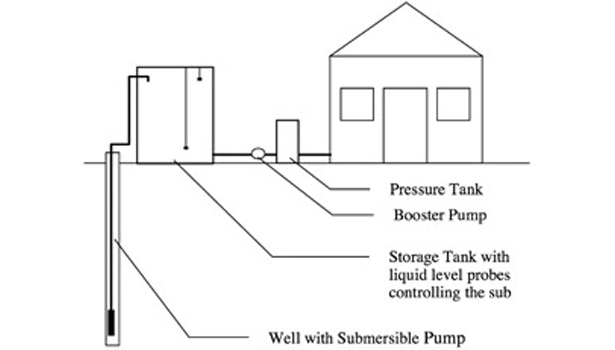

Figure 1 - Non-pressurized storage tank with booster system

Figure 2 – Non-pressurized storage tank.

Figure 3 – Alternating Relay

There are many situations where the water demand on a well water system exceeds the production capacity of the well. For instance, 10 gpm is typically considered the minimum flow rate needed to adequately supply a single family residence. But what if the well only produces three gallons per minute? That three gpm totals quite a lot of water over a 24 hour period (4,320 gallons, were the pump to run continuously) and a non-pressurized storage tank can make that well quite capable of satisfying the water needs of that residence.

Another example would be a property that has a well with enough capacity to supply the normal needs of the residence, but local fire codes require that the homeowner have a water connection that will provide 60 minutes of water at 50 gpm and 45 psi. In this case, it makes sense to install a well pump that is sized to the performance of the well, pump into a large non-pressurized storage tank, and use a booster system to provide the needs of the residence and fire department.

A non-pressurized storage tank, as opposed to a pressure tank, receives water from the well for use during periods of peak demand. The use of a storage tank necessitates the use of a second pump called a booster pump, plus a pressure tank, sized and controlled the same way you do in a single submersible or jet pump system. The well pump will now be controlled by floats or sensors in the storage tank. See Figure 1.

Booster System Components

The well pump: First, size the well pump to the output of the well. There is no sense in using a 10 gpm pump in a three gpm well; it will cycle on and off excessively. If you cannot closely match the performance of the pump with the well, it may be necessary to throttle the discharge with a flow control valve rated at just above the output of the well.

In any slow-producing well application, it is essential to use some sort of dry well protection device to prevent the pump from running when the water level in the well drops below the inlet of the pump. A dry running submersible pump will destroy itself and/or its motor in short order. For submersible pumps, electronic devices such as SymCom’s Pump Saver or Franklin’s Pumptec monitor the power going to the pump motor and shut the pump off when they sense the pump beginning to run dry.

For jet pumps, since air entering the pump causes it to stop pumping and necessitates re-priming the system, it is important to take precautions to ensure the water level in the well does not drop below the inlet of the foot valve. To prevent air from entering the foot valve in a slow-producing well, use a long tailpipe. Because a pump cannot lift water more than 25 or so feet due to the limitations of atmospheric pressure, installing a 30-foot section of suction pipe below the injector will preclude the possibility of the water level being drawn down below the foot valve. As the well draws down, increasing the suction head on the injector, its pumping capacity slows down until it matches that of the well. With the foot valve set at 30 feet below the injector, even in a well with no production, air cannot enter the foot valve because the injector is not able to lift the last foot of water to empty the well. If the well is not deep enough to allow the use of a long tailpipe, use a liquid level probe set just above the inlet to turn the pump off should the water level drop to that point.

The well pump only needs enough head pressure capability to get the water from the pumping level in the well to the top of the tank, plus a safety margin of 10 percent or so, to compensate for wear. The second pump, the booster, covers the pressure requirements of the residence.

The booster pump: The pump that feeds the house from the storage tank is called a booster pump, and can be a submersible pump mounted in the storage tank, a shallow well jet pump, or a single or multistage centrifugal pump. It is sized just as we do for a single pump system to meet the flow and pressure requirements of the residence.

If you are using a submersible well pump in the tank as the booster pump, you should install a flow-inducing shroud that goes from below the motor to above the inlet of the pump to ensure adequate motor cooling. One can be fabricated from a piece of thin-wall 4-inch PVC or ABS pipe about the same length as the sub and motor. With a hacksaw, make three longitudinal cuts 4-inches long and evenly spaced around one end. Use a hose clamp to clamp the shroud to the pump just above the inlet screen. Use plastic tape to seal the upper end or the shroud where it passes over the wire guard. A perfect seal is not required.

If fire protection is a part of this system, the booster pump will need to be sized accordingly. The flow requirements of a fire protection system can vary from 20 to 60 gpm for a residential application, depending on local codes. As a minimum, go with the flow rate recommended by the firehose nozzle manufacturer or with what is required by local codes.

Using two booster pumps and an alternating relay: Let’s say your county code requires a 3,000 gallon storage tank and 50 gpm of flow at 45 psi for fire protection. If you are pumping from a storage tank, I recommend using an alternating pump system to provide 25 gpm for normal usage, and 50 gpm for firefighting. In such a system, you would install two identical booster pumps side by side at the storage tank. Each pump has the capability to meet the non-fire capacity requirements, and they can be operated simultaneously to meet the fire needs. In non-fire service, they alternate from one to the other using an alternating relay (see Figure 3). Each pump is on every other cycle of the pressure tank.

What if the tank is up on a hill a half mile away from the well pump? Next month we will talk about how to control the well pump in this situation.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!